|

Introduction

Cutting Tails

Cutting Pins

Conclusion

|

Introduction

The AngleMag was invented by Jeff Snell

in Australia and is the current state-of-the-art magnetic saw guide. The

AngleMag is extremely versatile and can be used not only to saw dovetails,

but also to help out in a whole bunch of applications in which accurate

sawing is needed. It even allows you to get perfect square results, and

it can function as a high tech, extremely versatile mitre box.

Click here to order an AngleMag

|

|

In

the heady times of 19th century London, when cabinet shops turned

out thousands of chests, bureaus, and other furniture requiring

dovetails and other joints, a cabinetmaker was trained to mark out,

saw accurately, and make tight joints as second nature. There are

three reasons they could do this: first, an apprentice who couldn't

get the hang of it quickly would get fired or find another line

of work. Second, cabinetmakers in big shops had areas of specialties,

so the apprentices who cut the joints probably did little else.

Finally, practice makes perfect - after the first few thousand joints

you get good at it.

But

nowadays many woodworkers have trouble with dovetailing. You need

to lay out a joint and then saw it accurately. Sawing is the part

that most people have trouble with. Sawing dovetails freehand can

be learned with practice and attention. We recommend it for everyone.

But until you have this skill - or if you're doing extensive dovetailing

on a particular project, a magnetic saw guide is the easiest way

to ensure consistent results and get whatever spacing or custom

look you want. You will still have to accurately lay out the joint,

you will still have to chop the dovetails, but the hardest step

- sawing consistent straight lines - will be a thousand times easier.

|

| For

the purposes of this instruction we will concentrate on through dovetailing.

We don't want to go into the science of dovetailing - there are better

guides then this, and the instruction manual for the AngleMag gives

detailed instructions on all the different setups you can use for

many kinds of joinery. What we want to do is show you how to use the

AngleMag and point out the basics of dovetailing. Most of what we

talk about applies to all sorts of joinery and chisel use, but here

we are just tapping into the features of the AngleMag. |

|

The

Anatomy of the AngleMag

|

|

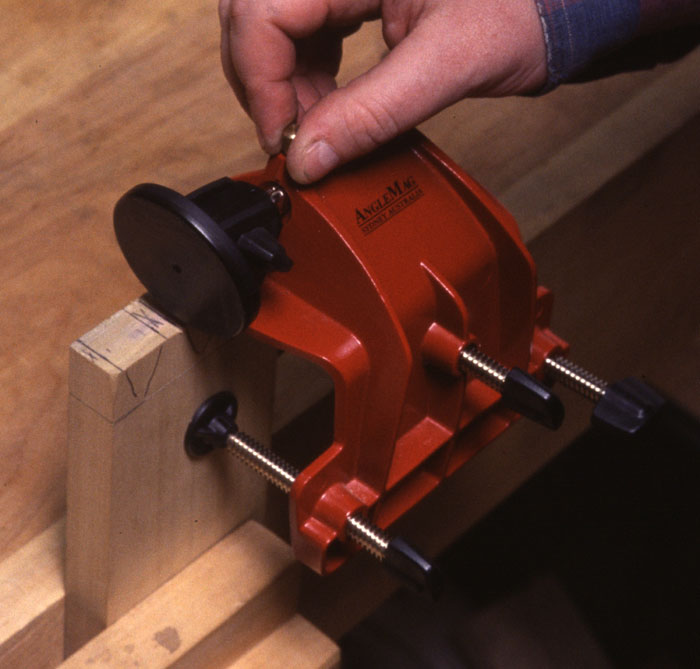

The

AngleMag is very simple in concept. It consists of an aluminum body

that clamps onto the work. For wide wood, you can use all three

clamps; for narrower stock, even a single clamp works well. The

important thing is that the AngleMag is clamped consistently with

the body flush down onto the end of the work. You can clamp wood

up to 2" thick, which adds a lot to its versatility. The body of

the AngleMag holds the guide shaft. The guide shaft is a rod with

grooves milled into it and a magnetic guide at one end. The angle

of the guide can be adjusted from straight across to 45 degrees.

For dovetailing, you set the guide to whatever angle you want your

dovetails to be and lock it in place.

|

|

To

position the guide precisely where you want it to cut, you move

the rod and then lock it in place using the two small thumbscrews

on the top of the body, then tighten the thumbscrews into one of

the four grooves running the length of the rod. This is the key

to the AngleMag. To position the guide for accurate saw cuts going

the other way, you just rotate the rod and lock it in the opposite

groove. To switch from cutting the tails to the pins, or vice versa,

just rotate and lock the rod 90 degrees. Consult the manual that

comes with the AngleMag for more details on the operation.

|

|

The

Tools Required

|

|

The

tools required for use with the AngleMag are pretty basic - the same

you would use for most joinery and cutting dovetails. Our photos feature

the following tools: The Clifton No. 4 bench plane, which will be

used at the end to trim the joint smooth (in a pinch a sander could

be used). A good square and a combination gauge are used for accurate

layout. The bar clamps in the top of the photo represent the clamps

you will use when you glue the joint up - any type of clamp will do

as long as it is long enough. The Ashley Iles chisels shown are part

of a very popular and highly rated set we carry and really represent

the classic English bench chisel at their best. The chisels are used

for removing the waste between the pins and tails, and possible trimming

of the joint to help the fit. We use a classic English mallet for

striking the chisels. You'll also note a pencil and layout knife,

and the two pieces of poplar we will be joining. But the most important

tools shown are the AngleMag and a large Japanese dozuki saw. |

|

Selecting

a Saw

|

| |

The

way the AngleMag works is simple: strong magnets hold your saw against

the guide so you saw straight. Unlike a mitre box or a non-magnetic

jig, magnets give the saw no place to wander. Almost any saw can

be used - even a saw that is less than ideal for unguided joinery

- because with the guide ensuring that the saw cuts straight, only

a saw that is seriously out of whack could cause a problem. The

important thing is that the saw is either unbacked or is wide enough

so that the saw can cut deep enough in the work before the back

interferes with the magnetic guide. A "short back" dozuki saw works

fine (and that's what we will be using here), as does a big Western-style

tenon saw.

The

particular saw we are using, a"short back" dozuki shown in the photograph

with all the other tools, is pretty inexpensive, has a fairly thick

blade (.5mm), and is filed combo rip / crosscut. It cuts fairly

slowly but because the AngleMag guides the saw this isn't a problem

and the saw is great for this purpose.

|

| |

A Japanese

ryoba saw like the one at left, has teeth on both sides of the blade.

One side of the saw is filed for rip cutting and the other side is

filed crosscut. The saw isn't ideal to use with the AngleMag, because

teeth on the trailing side will damage the surface of the guide. But

since I don't own a unbacked single-edged rip saw (other than some

huge handsaws),when I next do a lot of dovetails, I might use an old

ryoba with the crosscut teeth purposely dulled so that I can use the

quick cutting rip teeth with the AngleMag. If you do mar the guide

a lot, you'll definitely appreciate that a replacement guide facing

is included with the AngleMag. |

|