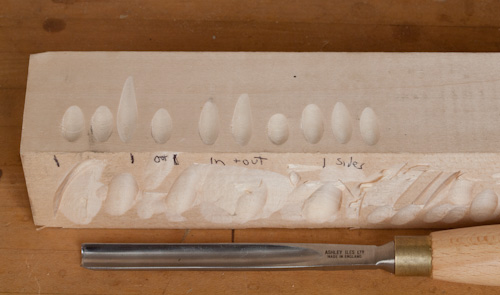

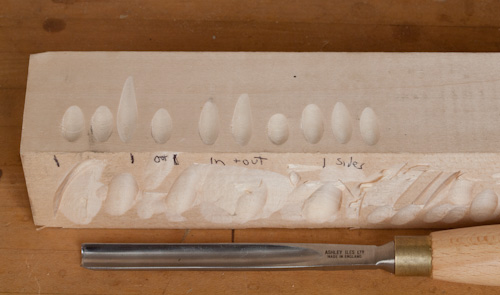

For years I have been pretty good and getting a tool sharp. However with my new interest in carving I've needed to bring "sharp" to a whole new level. The main picture is of a series of gouge cuts I made on basswood. Look at the second picture, which is a closeup of the left side of the stick of wood. Is the gouge sharp? For years I have been pretty good and getting a tool sharp. However with my new interest in carving I've needed to bring "sharp" to a whole new level. The main picture is of a series of gouge cuts I made on basswood. Look at the second picture, which is a closeup of the left side of the stick of wood. Is the gouge sharp?

I would have to say more or less. It's certainly not dull and we have a pretty smooth cut overall. These days this is the dullest I let my tools get. Notice on the sides of the cut there is a little ripping of the wood fiber, and as the tool is lifting up to exit the wood on the far end of the cut, the angle of attack is less than optimum and we see some fibers scratched and the bottom of the cut isn't smooth.

Since the tool isn't really dull I just spent a few minutes stropping the outside of the gouge. The fourth gouge cut from the left (on the right in the first close-up) shows the result. Not much change.

I kept on stropping the outside bevel of the tool but this time I also stropped the inside of the gouge with a bit of leather that has honing compound on its edge. I go back and forth between inside and out a few times just as I would chase a burr on a straight tool on a stone. It took a little practice when I started to be able to do this without ripping open my hand, but now I don't worry too much about that. I kept on stropping the outside bevel of the tool but this time I also stropped the inside of the gouge with a bit of leather that has honing compound on its edge. I go back and forth between inside and out a few times just as I would chase a burr on a straight tool on a stone. It took a little practice when I started to be able to do this without ripping open my hand, but now I don't worry too much about that.

The second close-up picture (which contains cuts five through eight) shows the result. The cut on the bottom of the gouge is clean going and coming. Actually this is pretty good. Except on closer reflection look at the edges of the cut in the middle of the stroke. This part is cut using the highest part of the sides of the gouge. There is a little bit of tear-out there. Not much, but some. The reason is that when I stropped the inside I obviously didn't spend enough time stropping the sides of the inside of the tool. It's an easy mistake to make and something I have to  consciously make sure I avoid. consciously make sure I avoid.

So I went back to my strops and spent a minute more making sure the sides of the gouge got stropped too.

The third close-up (further down on this page) shows the eighth, ninth and tenth cuts. On the ninth gouge cut (in the middle) you can see the result of making sure I strop the sides more - it's a very clean cut. The tenth and final gouge cut on the right is slightly smoother and might have taken less effort, marginally so on both counts. Before I made that cut I stropped again using a plain piece of leather both on the outside and inside of the tool.

There is a bit of a odd shadow on the left of the eight cut. I think it's caused by an uneven edge on the left of the tool. The final extra stropping minimized it and my guess is a little more stropping on the left side of the gouge would get rid of it. Nonetheless the tool is still cutting pretty smoothly on that side.

We stock a whole range of sharpening supplies and carving tools. Click here if you need a strop. Here if you need honing compound (one bar lasts a long, long time). Here is a lesson on sharpening chisels and plane irons. We stock a whole range of sharpening supplies and carving tools. Click here if you need a strop. Here if you need honing compound (one bar lasts a long, long time). Here is a lesson on sharpening chisels and plane irons.

If you need honing compund |

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

For years I have been pretty good and getting a tool sharp. However with my new interest in carving I've needed to bring "sharp" to a whole new level. The main picture is of a series of gouge cuts I made on basswood. Look at the second picture, which is a closeup of the left side of the stick of wood. Is the gouge sharp?

For years I have been pretty good and getting a tool sharp. However with my new interest in carving I've needed to bring "sharp" to a whole new level. The main picture is of a series of gouge cuts I made on basswood. Look at the second picture, which is a closeup of the left side of the stick of wood. Is the gouge sharp?  I kept on stropping the outside bevel of the tool but this time I also stropped the inside of the gouge with a bit of leather that has honing compound on its edge. I go back and forth between inside and out a few times just as I would chase a burr on a straight tool on a stone. It took a little practice when I started to be able to do this without ripping open my hand, but now I don't worry too much about that.

I kept on stropping the outside bevel of the tool but this time I also stropped the inside of the gouge with a bit of leather that has honing compound on its edge. I go back and forth between inside and out a few times just as I would chase a burr on a straight tool on a stone. It took a little practice when I started to be able to do this without ripping open my hand, but now I don't worry too much about that.  consciously make sure I avoid.

consciously make sure I avoid.  We stock a whole range of

We stock a whole range of

Some are made to be mounted on a tapered spindle for use on a low speed electric motor. Jewelry findings supliers.

I've nothing against buffs, tapered or otherwise, and in fact I have have two powered sharpening systems which I personally don't use much (no reason - just they are on the other end of the warehouse) but for this particular operation - stropping an already sharpish tool, I do this all the time as I carve and it only takes about a minute by hand.

My V-gouge is the hardest to sharpen evenly all around. I'll just keep practicing and hope that eventually it'll take less time to get it right every time.

suggests using various wood strops that have been lightly rubbed with honing compound. Does not dub edges as leather can but, more important, you can easily make the exact shape any gouge or chisel needs - simply use your tool to make a straightish ( not that important)concave cut in a piece of scrap, rub this hollow with honing compound and you have a "custom " strop for that tool.Opposite for the inside of the gouge - or just use a piece of dowel. Cheap, takes no time. Book explains well.

I know of the system you describe and lots of people like it (yourself included). I've never had a problem with a leather strop dubbing anything and I would much rather a single strop where one size fits all. In my current setup - a flat strop for the outside and a thick edge of leather for the inside (horse butt is about 3/16" thick) and it works brilliantly.

As a custom knifemaker my "Hand Shapened" edges have quite a following. I use mainly large Eze-Lap Diamond stones for the "setting up" of the edge. My Diamonds go from 220 grit to 1200 grit. If the steel in the blade will take it, and most any I work with will, I use the strops to "Refine" the edge to whatever level will work best for that particular steel, it's temper, and it's grind, to name just a few variables.

I've used strops for many a year and keep a few close by when I am relaxing doing a Relief or Abstract woodcarving. Depending on the wood I am working with, I may have to strop every couple of dozen cuts. I find that by keeping my tools, both working knives and my Ashley Iles woodcarving tools "Stropped up" I get much more cutting time between sharpenings.

I do not purchase any commercial strops perfering to make my own as they tend to work much better and fit my particular need much better.

I started out using cut lengths of 2"x4" that worked very well particular on long knives and custom machetes. I attach the cowhide to the wood using a good grade of glue that can be found on this website or in a hardware store. I have also used Joel's "Horse Butt" leather strop to very good advantage!

Hope this helps.

Cordially,

Coyote

[[[[[End of Msg]]]]]